how to install led street light

The street lamp construction process is as follows:

Measuring and fixing lamp positions—digging trenches—burying pipes—pouring street lamp foundation—laying cables, installing street lamp control cabinets—insulation testing, road lamp installation—testing, debugging—self-inspection—completion acceptance.

(1) Measure and fix the lamp position

Before the start of construction, according to the construction drawings and site conditions, accurately determine the installation position of the street lamp based on the designed lamp position spacing to ensure that the elevation of the street lamp is flush with the top surface of the curb.

(2) Trenching

Before excavation, first measure and release the excavation center line, and sprinkle the center line with white ash.

During the excavation, there should be measurement cooperation guidance, and do not over-excavate or under-excavate. After the excavation, it passes the self-inspection and reports to the supervision engineer for acceptance, and then enters the next process of construction.

According to the actual geological conditions of the site, excavate the street lamp foundation and the pre-buried trench for cable pipes according to the construction drawings. When excavating the soil, use manual construction with excavators, and use manual excavation when the trench is excavated to the final 20cm. And carry out the leveling treatment of the base. The foundation of the street light is artificially solid.

(3) buried pipe

According to the construction drawings, the corresponding cable pipes are pre-buried, and the appearance inspection is carried out before the pipes are lowered. If cracks, bends and other defects are found, they should be replaced before the pipes are lowered.

(4) Pouring the street lamp foundation

Formwork support shall be carried out according to the size of the drawings. The formwork shall be made of wood formwork. After the support is completed, the steel bars shall be installed and the embedded parts and threading pipes shall be buried. The next process is construction.

(5) Apply grounding wire

The ground electrode is processed according to the quantity and material specifications specified in the design. The grounding electrode should use a 2.25-meter steel braze and be reliably welded to the foundation cage. After the connection is completed, the quality inspection department should be asked to conduct hidden inspections in time.

The material, position, welding quality, and cross-sectional specifications of the grounding body should all comply with the design and construction acceptance specifications. After passing the inspection, the next process can be carried out.

The pre-embedded pipe used for passing the cable should be galvanized steel pipe, which can be customized according to the specification, length and shape specified in the design. It is fixed on the steel frame before concrete pouring, and the two ports are sealed with plastic cloth or tape to prevent concrete from entering the steel pipe during pouring and scratching the cable when passing through the cable.

(6) Template installation

The formwork adopts wood formwork or combined steel formwork, and the geometric dimensions must not be smaller than the design value, and the reinforcement must meet the rigidity and stability requirements to ensure that the formwork does not run or expand when pouring concrete.

(7) Concrete pouring

Alkali pouring should be symmetrical and carried out in layers, the thickness of each layer should be controlled at 25-30cm, and a plug-in vibrator should be used for construction.

Check the positions of embedded parts, steel bars and formwork while vibrating during vibration, and correct any displacement if found. After the pouring is completed, check the embedded parts again to ensure that the embedding position complies with the specifications and design requirements.

(8) Street lamp installation

Foundation cleaning: clean the threaded tape of the foundation embedded parts, smooth the concrete surface, and install the lamp pole flange.

Check lamps: All lamps should be electrified before installation, and they can be installed in place after passing the test. After all lamps are installed, all lamps should be electrified again, and finally fixed after adjusting the projection angle.

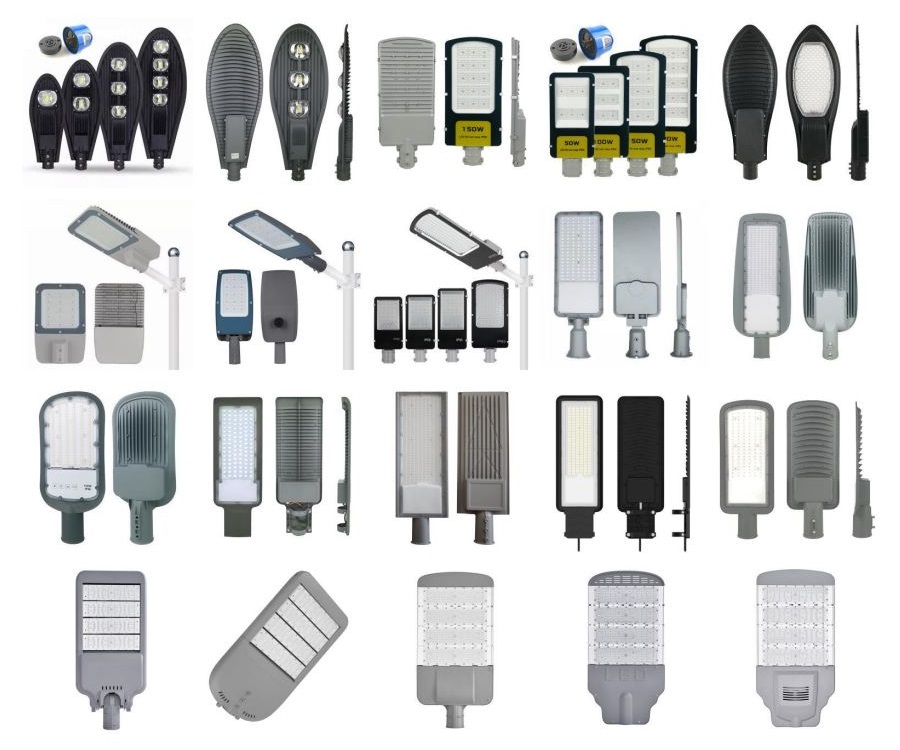

Recommended style

Alibaba Platform: https://gzyaoliang.en.alibaba.com/

I am not sure where youre getting your info but good topic I needs to spend some time learning much more or understanding more Thanks for magnificent info I was looking for this information for my mission